top of page

Getting You Back to Work Fast

USED EXCAVATOR PARTS

We will BEAT the price on ANY used OEM 20/30/40 tonne Excavator part (subject to availability)

Choosing the Right Hydraulic Oil for Your Excavator — And Why It Affects Part Lifespan

Hydraulic systems are the heart of an excavator.Power, precision, lift capacity, digging strength — it all comes down to one thing: The hydraulic oil you choose. Pick the right oil, and your pumps, valves, cylinders, and final drives last thousands of extra hours.Pick the wrong oil, and you’ll destroy components faster than any operator mistake can. Most excavator owners know oil matters — but very few understand why it matters.This blog breaks down the science, the logic, a

RALPH COPE

Dec 11, 20254 min read

How to Check the Condition of a Used Final Drive Before Buying

(An educational, step-by-step guide for anyone purchasing used OEM final drives in South Africa) A final drive isn’t just another excavator part.It ’s the heart of your machine’s travel system — and one of the most expensive components you’ll ever replace. Buying used OEM final drives is one of the smartest ways to save money… if you know how to check their condition properly. Because let’s be honest:A final drive can look fine on the outside and still be an expensive disas

RALPH COPE

Dec 11, 20254 min read

Why OEM Turbochargers Last Longer — The Engineering Behind Boost Systems

An Educational Guide for Excavator Owners, Mechanics & Fleet Managers in South Africa Turbochargers are one of the hardest-working components on any excavator engine. They spin at over 100,000 RPM , survive extreme heat, and feed the engine the extra air it needs to produce torque under heavy load. But here’s the part most people get wrong: A turbocharger is not just a “bolt-on part.” It’s a precision-engineered system that must match the engine’s airflow, exhaust pressure, t

RALPH COPE

Dec 11, 20254 min read

Why OEM Part Numbers Matter: How to Decode Them Like a Pro

(Educational, clear, practical — written for real excavator operators and buyers in South Africa) When you walk into a parts yard or message a supplier, the first thing they’ll ask isn’t your excavator’s colour, bucket size, or where it last got stuck in the mud.They’ll ask you one thing : “Do you have the OEM part number?” For many machine owners, that question instantly triggers panic. They flip open a manual from 2004, scratch their heads, and pray the number they send isn

RALPH COPE

Dec 10, 20254 min read

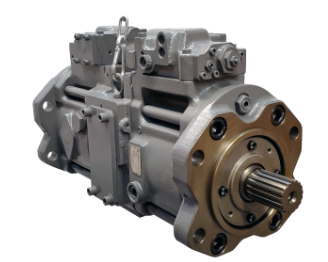

The Most Common Causes of Excavator Pump Failure — and How to Avoid Them

When an excavator pump fails, everything fails.No digging. No lifting. No swinging. No productivity.And no contractor wants to explain to a client why an entire site is standing still because the heart of the machine just died. The bad news? Pump failures are expensive — sometimes the most expensive repair an excavator will ever need. The good news? Most pump failures don’t happen overnight. They build up slowly, silently, and predictably. And even better — they are highly p

RALPH COPE

Dec 10, 20255 min read

Why Track Tension Matters — And How Incorrect Tension Damages Your Excavator

If you want to destroy an undercarriage faster than a bulldozer on a wet hillside, run your excavator with the wrong track tension. It’s one of the most overlooked forms of excavator maintenance , yet incorrect track tension is responsible for thousands of hours of unnecessary wear — and millions of rands in avoidable undercarriage repairs every year. Most operators don’t check track tension.Most site managers don’t enforce it.Most contractors only notice a problem when the m

RALPH COPE

Dec 10, 20254 min read

The Hidden Costs of Poor Hydraulic Maintenance (And How OEM Used Parts Save Your Wallet)

Hydraulics are the beating heart of your excavator. You blow that system, and you’re not just dealing with a repair — you’re dealing with a full-scale financial ambush. Operators complain about fuel costs, attachments, labour, insurance… but the one thing that quietly drains bank accounts across South Africa is poor hydraulic maintenance . And yes — it’s avoidable.And yes — most contractors know better.But no — they don’t do better. This blog breaks down exactly how skipping

RALPH COPE

Dec 9, 20254 min read

The Lifecycle of an Excavator Component: From New to Scrap

Every excavator part has a story. Some live long, some die young, and some soldier on through rebuild after rebuild until they finally give up and get thrown onto the scrap pile behind a workshop in Germiston. Understanding the full lifecycle of an excavator component helps you: plan maintenance better budget more accurately know when to repair instead of replace avoid catastrophic failures buy smarter when sourcing used OEM parts Most failures don’t come out of nowhere — th

RALPH COPE

Dec 8, 20254 min read

How to Tell If Your Excavator Part Can Be Repaired or Needs Replacing

Stop Wasting Time, Money, and Sweat on Half-Assed Repairs Let’s get straight to the point: Most contractors are terrible at this .They stand over a busted final drive, hydraulic pump, or swing motor and say, “I think we can fix it.” And then three days later, the machine is still broken, your operator is pissed, the client is furious, and your wallet is getting fleeced faster than diesel prices. Here’s the brutal truth: some parts are worth repairing. Most aren’t. If you don’

RALPH COPE

Dec 7, 20254 min read

How to Identify Early Signs of Excavator Final Drive Failure

Stop Waiting for a Catastrophe — Catch It Before It Costs You a Fortune Let’s not sugarcoat it: final drives are expensive, critical, and delicate . Most contractors only notice they’re failing when the machine stops moving, oil sprays everywhere, and panic sets in . By then, you’re looking at: R80,000+ in repair or replacement Days of downtime Angry clients breathing down your neck Labour and hire costs piling up So, here’s the hard-hitting truth : You need to spot the signs

RALPH COPE

Dec 7, 20254 min read

How to Choose the Right Supplier for Used Excavator Parts in South Africa (And Why Most Get It Completely Wrong)

A Brutally Honest Guide for Contractors Who Are Tired of Being Screwed Over Let’s not dance around it. The used excavator parts market in South Africa is a jungle —and most suppliers are hyenas. You already know the type: “We’ve got stock” (they don’t) “It’s 100% OEM, boss” (it’s not) “Machine was running” (it wasn’t) “We’ll courier it today” (nope) “Looks the same, so it should fit” (it won’t) If you’ve been in the construction or plant hire game for more than five minutes,

RALPH COPE

Dec 5, 20255 min read

The Real Cost of Excavator Downtime (And How Used OEM Parts Save You a Fortune)

A Hard-Hitting, South African, Contractor-to-Contractor Reality Check Let’s cut the crap. Every contractor in South Africa thinks they understand the cost of downtime… until their excavator dies in the middle of a job, the client starts phoning every hour, and their crew stands around scratching their balls while billable hours burn like tinder. Most guys only count the price of the replacement part.R5,000 here. R12,000 there. Cute. But that’s not the real cost.Not even clos

RALPH COPE

Dec 5, 20254 min read

The Role of the Pressure Release Valve in Your Excavator

Why This Small Component Keeps Your Machine Running and Prevents Costly Damage When it comes to excavators, most contractors focus on engines, hydraulics, and tracks — and overlook one of the most critical components : the pressure release valve . This little device does big work , protecting your hydraulic system, extending the life of components, and preventing catastrophic failures. Here’s a detailed, contractor-friendly guide to understanding it, spotting issues, and keep

RALPH COPE

Dec 4, 20254 min read

How a Steel-Tracked Excavator Changes Direction When Moving

Stop Guessing — Understand the Mechanics Before You Break Your Machine If you think turning a steel-tracked excavator is as simple as “push one track forward and pull the other back,” think again. The truth? Most contractors don’t fully understand how their machines actually change direction , and it costs them — in: Premature track wear Final drive failures Hydraulic motor damage Lost time and money on site This is the hard-hitting, no-BS guide to how your excavator really t

RALPH COPE

Dec 4, 20253 min read

How to Tell If Your Excavator Part Can Be Repaired or Needs Replacing

Avoid Costly Mistakes and Keep Your Machine Running Longer Every contractor knows the sinking feeling: a critical excavator component fails, and suddenly you’re facing downtime, lost income, and a looming repair bill . The tough truth: not every broken part is worth repairing. But how do you know which ones are? This guide walks you through practical, hands-on ways to decide whether to repair or replace a component — saving time, money, and headaches on South African sites.

RALPH COPE

Dec 3, 20253 min read

10 Excavator Parts That Are Better Bought Used Than New

Save Money, Reduce Downtime, and Get OEM Reliability Without Paying OEM Prices When an excavator breaks, you’ve got two problems: the machine is down, and your wallet is about to cry. Modern OEM parts are insanely expensive — especially from brands like Volvo, CAT, Komatsu, Hitachi, Doosan , and Hyundai . Even simple components can cost more than the entire machine is worth if it's older or high-hours. But here’s the truth smart contractors understand: Some excavator parts ar

RALPH COPE

Dec 2, 20255 min read

The Ultimate Guide to Identifying High-Quality Used Excavator Parts

How to Make Sure You’re Getting the Best OEM Components (and Not Expensive Scrap Metal) Buying used excavator parts can save your business a ton of money — but only if you know how to identify what’s high-quality and what’s a ticking time bomb . The harsh reality of the used parts world is this: There’s good stock…There’s bad stock…And then there’s the absolute horror show that some sellers try to pass off as “good condition.” At Vikfin, we’ve built our entire reputation on s

RALPH COPE

Dec 2, 20255 min read

Komatsu PC400 vs Hitachi ZX450: Which 40-Tonne Machine Actually Costs You the Least Over Its Lifetime in 2026 South Africa?

Howzit, legends of the dig. Ralph in Benoni and Justin in Cato Ridge here. Between us we’ve personally stripped 47 Komatsu PC400-series (Dash-6 right up to Dash-8M0) and 38 Hitachi ZX450/ZX470/ZX490 machines since 2018. That’s 85 complete 40-tonne carcasses turned into pallets of parts that are earning contractors money from Kathu to Kitwe right now. We’re not brand fan-boys. We sell whatever walks through the gate. But when the numbers are this one-sided, we have to call it.

RALPH COPE

Dec 1, 20254 min read

The Muscle Behind the Boom: Understanding the Excavator Dipper Arm Cylinder

When you watch an excavator in action, it’s easy to focus on the big stuff — the roaring engine, the swinging boom, the bucket biting into the earth. But behind every precise movement, there’s a powerhouse component working under immense pressure to make it all happen: the dipper arm cylinder . It’s one of those parts that most operators only think about when it starts leaking — but by then, you’re already losing power, precision, and money. At Vikfin , South Africa’s trusted

RALPH COPE

Nov 4, 20258 min read

Keeping Tension in Check: The Crucial Role of the Excavator Track Adjuster

When it comes to excavators, most operators think power means horsepower, torque, or hydraulic muscle. But there’s another kind of power hiding down below — one that doesn’t get the spotlight but literally keeps the whole machine moving. It’s the track adjuster , and without it, your excavator wouldn’t get far. This small but mighty component ensures your tracks stay tight, your undercarriage stays aligned, and your productivity stays on track — literally. At Vikfin , South A

RALPH COPE

Nov 4, 20257 min read

bottom of page